NATIONAL ALTERNATIVE UNITS

COMPANY PROFILE

A modern breeding equipment manufacturer integrating design, R & D, production, sales and service.

Shandong Wangfu is committed to providing advanced modern, high-efficiency and energy-saving feeding equipment for the global pig industry. It has a professional technical team focusing on the R & D and production of feeding equipment. It is at the leading level in the industry in terms of product design concept and manufacturing process. Now it has won 8 national patents, providing strong technical support for solving feed waste, optimizing feeding methods and improving the efficiency of pig farms.

The company's products are sold all over the country and many countries and regions in the world. It is well-known in the pig industry at home and abroad for its high-quality professional service and sincere and diligent attitude.

ABOUT WANGFU

Shandong Wangfu is committed to providing advanced modern, high-efficiency and energy-saving feeding equipment for the global pig industry. It has a professional technical team focusing on the R & D and production of feeding equipment. It is at the leading level in the industry in terms of product design concept and manufacturing process. Now it has won 8 national patents, providing strong technical support for solving feed waste, optimizing feeding methods and improving the efficiency of pig farms.

The company's products are sold all over the country and many countries and regions in the world. It is well-known in the pig industry at home and abroad for its high-quality professional service and sincere and diligent attitude.

Products Center

Water Material Square Plate Mixing Tank

2. Through the adjustment plate, control the amount of feed output, how much to eat, and how much to eat;

3. The world's first feeder device solves the problem of uneven feeding of powdery materials.

Water Material Disc Mixing Tank

2. It can be used for nursery pigs and fattening pigs, and is suitable for pellets and powders that meet national standards;

3. The feed in the pan does not accumulate to achieve the ideal feeding effect, reducing the mildew and waste of the feed;

4. The piglets can be used after weaning for 21 days until they are put into slaughter;

5. No need to power on, no sensor, no chip, easy to operate, easy to use, durable, no maintenance costs;

6. The water inlet end is equipped with a water quality filter to filter the magazines in the water to make the water quality cleaner;

7. Release 15 days in advance, saving 1%-2% of feed.

Thin Barrel Disc Dry Feed Trough

2. 110 liter plastic drum, anti-oxidation, impact resistance, long service life

3. P3 type large feeding tray saves energy and reduces consumption

3. The built-in anti-clogging device can unblock the material

4. Innovative discharge stabilization device, uniform discharge

5. Cross in the barrel, ordinary galvanized bracket.

6. The discharge volume can be adjusted, and the adjustment device is smooth and durable

Wet and Dry Round Plastic Bucket

2. Material tray: 1. 5mm thick 304# stainless steel plate molding

3. The built-in anti-clogging device can unblock the material

4. The discharge volume can be adjusted, and the adjustment device is smooth and durable

5. Stainless steel involute device in the barrel

6. The innovative full-drive full-moving feeder discharges evenly

Wet and Dry Flat Plastic Bucket

2. Material tray: 1.0mm thick 304# stainless steel plate molding;

3. The built-in anti-clogging device can unblock the material;

4. The discharge volume can be adjusted, and the adjustment device is smooth and durable;

5. Cross in the barrel, ordinary galvanized bracket;

6. The innovative full-drive full-moving feeder discharges evenly.

Wet and Dry Rotomolding Plastic Bucket

2. 110 liter plastic drum, anti-oxidation, impact resistance, long service life

3. P2 type large material tray saves energy and reduces consumption

4. The built-in anti-clogging device can unblock the material

5. Innovative discharge stabilization device, uniform discharge

5. Cross in the barrel, ordinary galvanized bracket

6. The discharge volume can be adjusted, and the adjustment device is smooth and durable

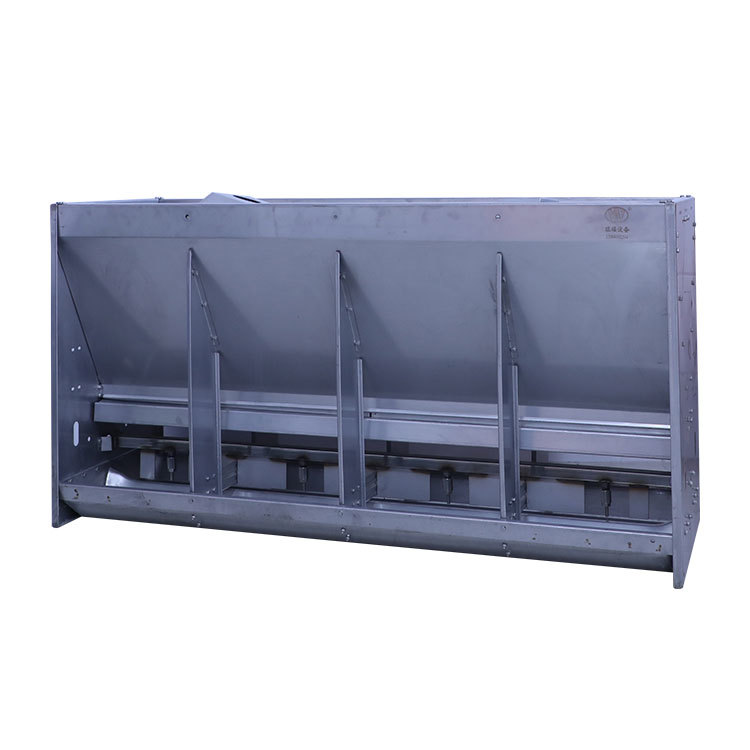

Wet and Dry Square Slot For Screw Assembly

2. The design of large partition board avoids pigs playing and scrambling and saves feed;

3. The platform eats the feed, and controls the feed output through the adjustment plate, how much to eat, and how much to eat;

4. Reduce energy.

New Stainless Steel Wet and Dry Square Tank

2. It can be used for nursery pigs and fattening pigs, and is suitable for pellets and powders that meet national standards;

3. The feed in the pan does not accumulate to achieve a good feeding effect, reducing the mildew and waste of the feed;

4. The piglets can be used after weaning for 21 days until they are put into slaughter;

5. No need to power on, no sensor, no chip, easy to operate, easy to use, durable, no maintenance costs;

6. The water inlet end is equipped with a water quality filter to filter the magazines in the water to make the water quality cleaner;

7. Release 15 days in advance, saving 1%-2% of feed.

NEWS

07-22

2022

07-22

2022

Scan and follow Wangfu official account

TEL:+86-13864102294

ADD:Xi Dong sub district office Fang Zi Cun, Zouping City, Binzhou City, Shandong Province

Webpage Copyright:Shandong Wangfu Agricultural Machinery Co., Ltd SEO

+86-13864102294

+86-13864102294

1758843515@qq.com

1758843515@qq.com